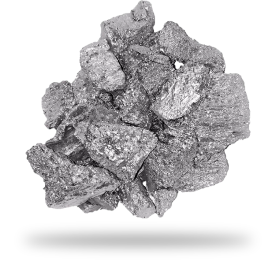

Flakes

Manganese

Manganese is too brittle to be of much use as a pure metal. It is used mainly in alloys, such as steel.

Steel contains about 1% manganese to increase strength and improve workability and wear resistance.

Manganese(IV)oxide is used as a catalyst, as a rubber additive and to decolorize glass, which is colored green by iron impurities. Manganese sulfate is used to make a fungicide.

Manganese(II)oxide is a strong oxidizing agent and is used in quantitative analysis. It is also used in the manufacture of fertilizers and ceramics.